Automatic rivet nut and threaded sleeve installation workstation

Product introduction

The automatic riveting nut and thread sleeve installation workstation includes functions such as blowing, installation, identifying hexagonal hole angles, tension monitoring, stroke monitoring, torque monitoring, tail breakage, tail removal, monitoring for removal, and exporting reports.

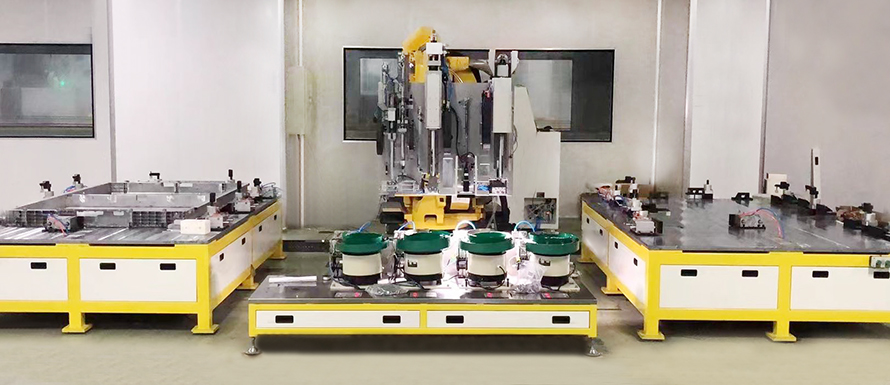

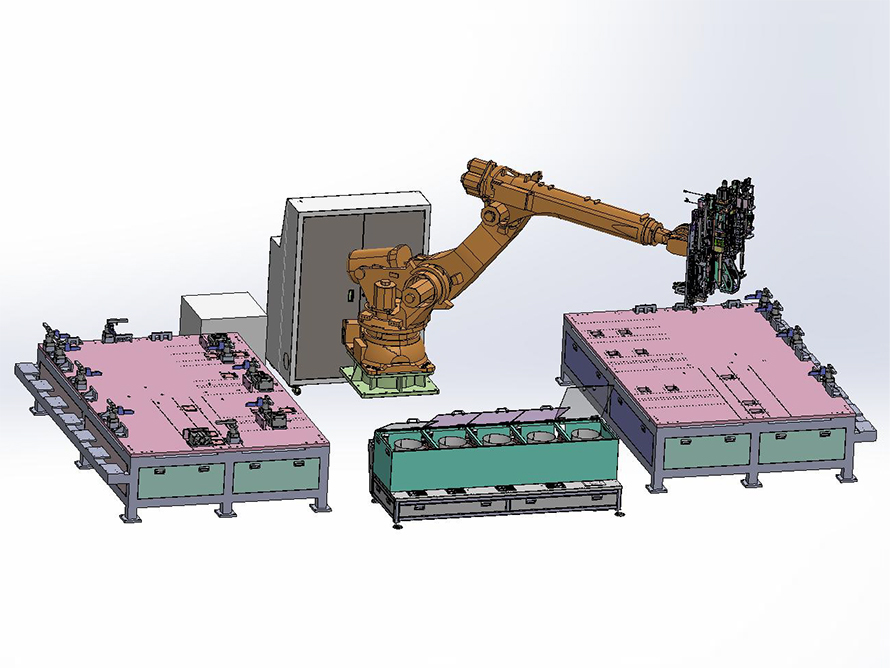

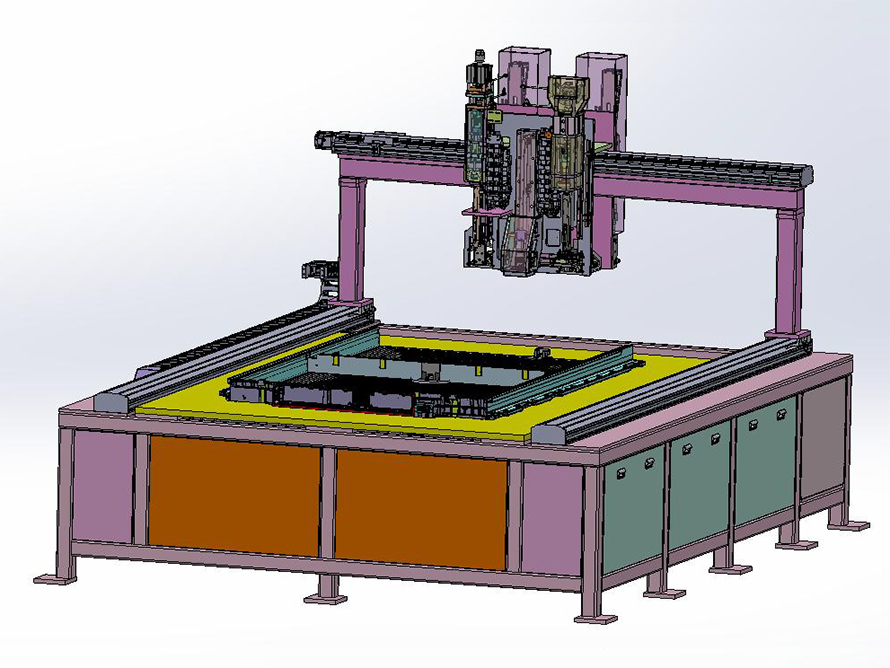

Different versions

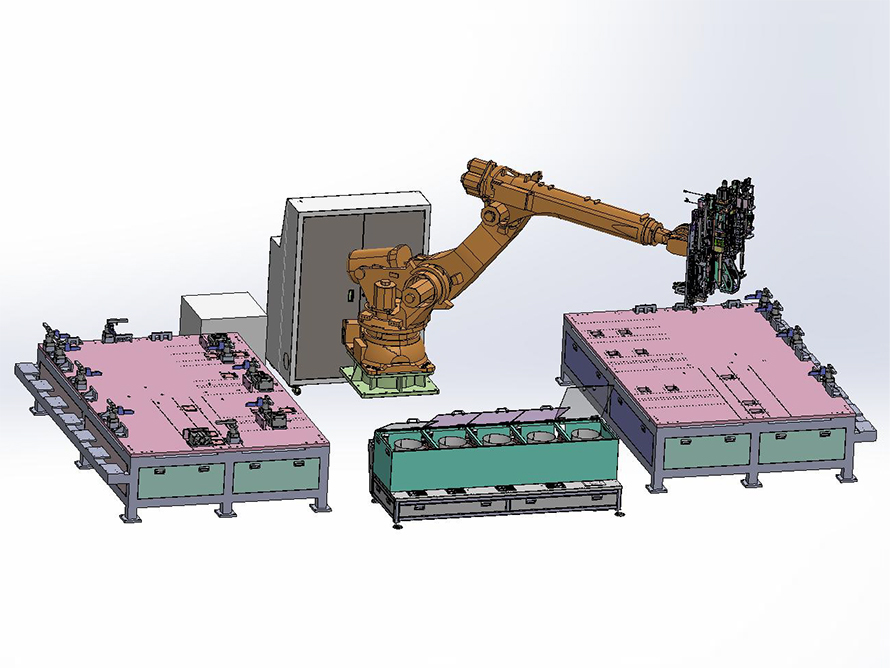

Robot version |

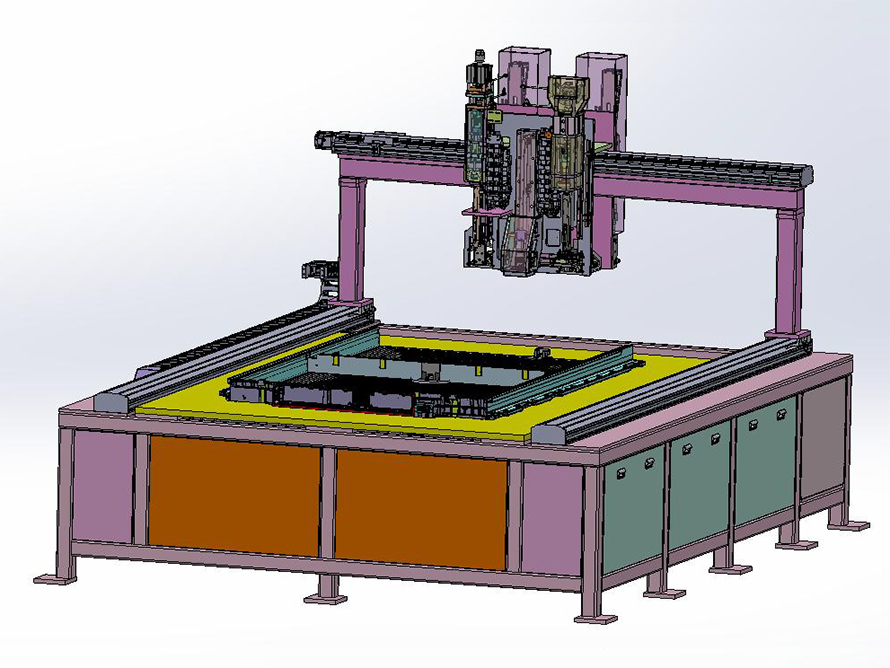

Gantry version |

Cost performance ratio: gantry version>robot version

Running speed: gantry version>robot version

Flexibility: Robot version>Gantry version

Floor area: robot version>gantry version

Common functions (combination): installation of rivet nuts, installation of threaded sleeves and tail breakage detection, visual detection, dispensing, and other functions, which can be combined arbitrarily.

You can choose different models and more functions according to different occasions and production requirements, just replace the actuator (dispensing, CCD detection, go stop, etc.).

Product features

● The self opening mold blowing pipe, screw sleeve and rivet nut can achieve automatic remote blowing and automatic correction, solving the problem of low installation efficiency for large products.

● Automatic control of thread sleeve installation depth, automatic switching (1D-5D), and installation torque monitoring.

● The threaded sleeve head can be recognized when it comes into contact with the workpiece, automatically eliminating the deformation of the workpiece.

● Complete process automation of threaded sleeves: 1. Automatic material retrieval; 2. Automatic installation; 3. Automatic tail breakage; 4. Automatically remove the broken tail and check if it is removed; 5. Automatic NG not removed.

● Suitable for steel wire threaded sleeves, self tapping threaded sleeves, gap threaded sleeves, military standard and non-standard threaded sleeves.

● The riveting stroke can be adjusted according to the yield strength of the riveting nut, and the height after riveting can be automatically adjusted.

● Tension monitoring and travel monitoring, installation fault feedback and alarm recording.

● The riveting machine head can be recognized when it comes into contact with the workpiece, automatically eliminating the deformation of the workpiece.

● Suitable for hexagonal rivet nuts (automatic angle recognition), cylindrical knurled nuts, through hole nuts, blind hole nuts, etc.

● Equipped with a CCD vision system, the product can be accurately positioned and connected to the MES system for installation data storage and traceability.

● It can match dispensing, oil dispensing, go/no go gauge detection, etc. for different usage scenarios, and customize according to different customer usage scenarios to further improve automation efficiency.

Application examples

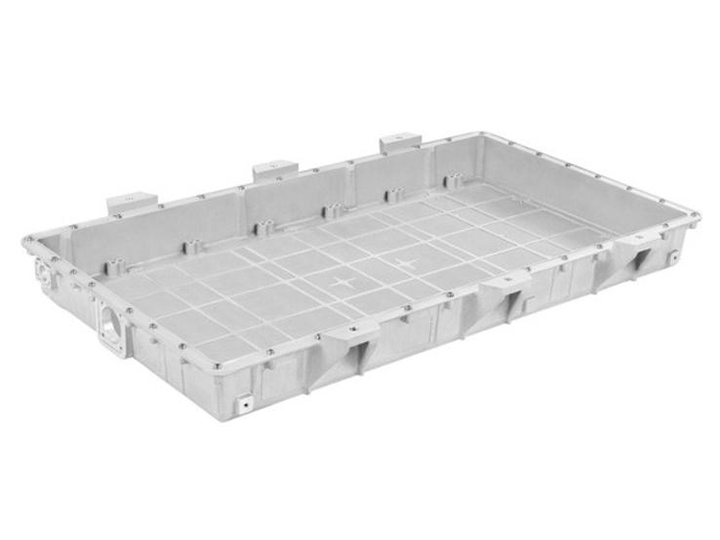

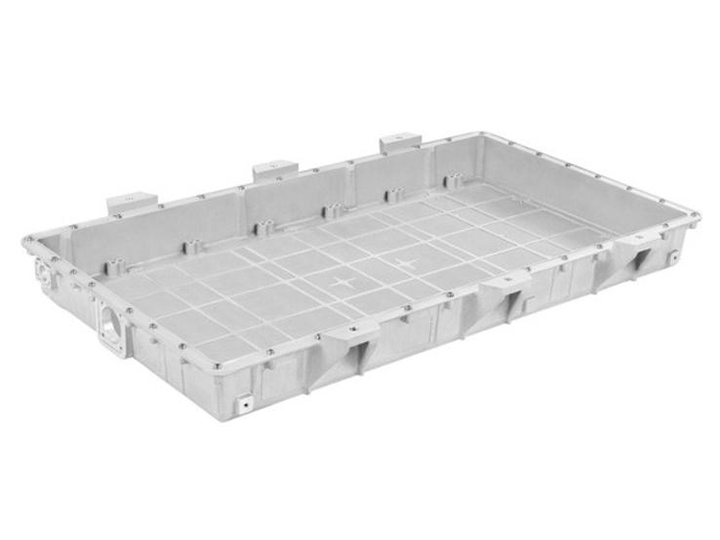

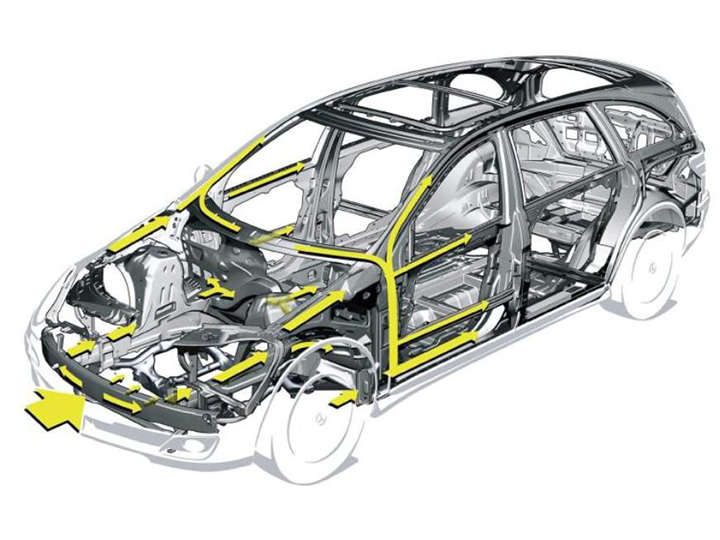

New energy vehicle battery tray |

Aerospace |

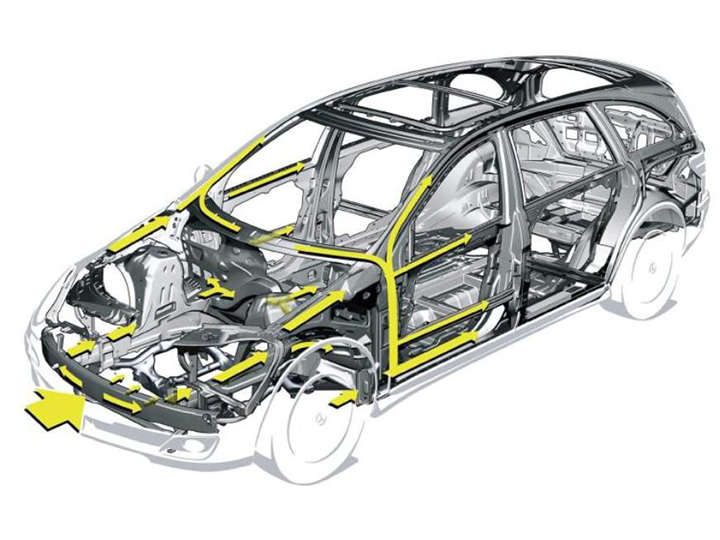

Auto parts |

Specification parameters

|

Type |

Automatic installation of rivet nut/threaded sleeve workstation |

|

Product size |

Customizable according to needs |

|

Process type |

Customizable according to needs |

|

Installation speed |

Customizable according to needs |

|

Material supply method |

Blowing/moving material retrieval |

|

Repetitive accuracy |

+/-0.05mm |

|

Operating speed |

600mm/sec(X-Y) |

|

Control system |

WINDOWS system/PLC+human-machine interface+MES |

|

Loading method |

Customizable according to needs |

|

Applicable product objects |

New energy vehicle power battery trays, aerospace, medical equipment, metal castings, automotive accessories, etc |

|

Optional other features |

Can match dispensing, oiling, tail breakage, go/no go gauge detection, etc. for different usage scenarios |

|

Automatic function |

Functions such as material blowing, installation, identification of hexagonal hole angle, tension monitoring, stroke monitoring, torque monitoring, tail breakage, tail removal, and monitoring for removal |

|

Overall dimensions |

Based on actual specifications |

|

Rated voltage |

Three phase electricity 380V/AC 100V-230V 50-60HZ |

|

Environmental resistance |

-10~50 ℃, dust-free and non corrosive gas |

|

Weight |

Based on actual specifications |