Injection molding machine loading and unloading machine

|

|

Product advantages

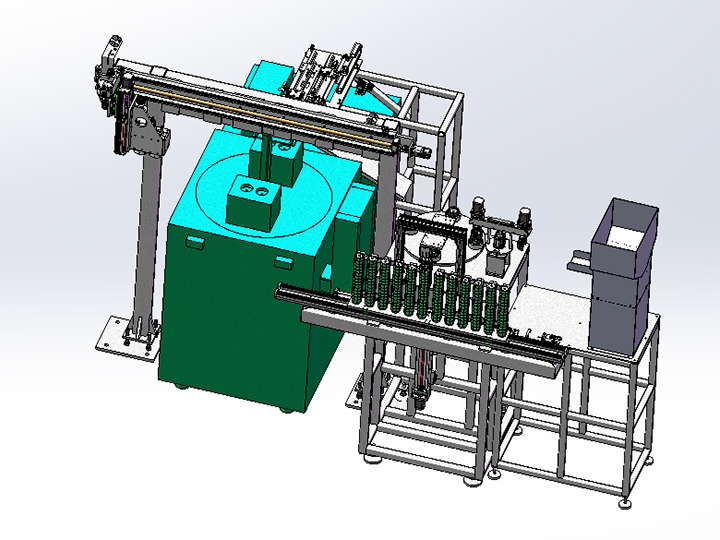

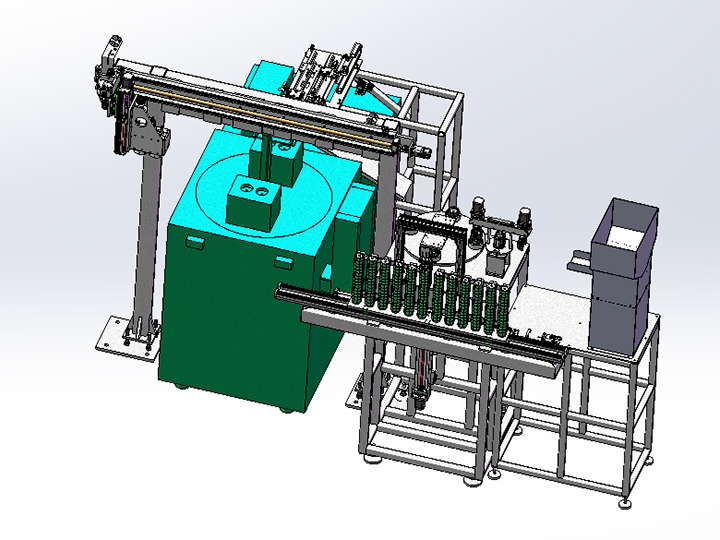

In order to improve the production efficiency and facilitate the cutting, after the injection molding is completed, the corresponding unloading device needs to be matched. The unloading device is mainly realized by the robot controlled by the automatic control, in the production process of the diving mobile phone case, when diving in the mobile phone case After the film is placed in the camera hole, a laminate is required to be poured around the film to press the film to prevent the film from falling from the diving mobile phone case. During operation, the robot first extends into the interior of the injection molding machine, and the diving of the pressure plate is injected. The mobile phone case is removed, and the diving mobile phone case without the injection molded plate is placed inside the mold.

The existing manipulator mainly comprises a frame, the frame is provided with a horizontal sliding rail, the horizontal sliding rail is slidably connected with a longitudinal sliding rail, and the vertical sliding rail is vertically connected with a positioning plate, and the setting plate is provided with A plurality of sets of suction cups for respectively sucking the uninjected diving mobile phone case and the already-injected diving mobile phone case. When working, the worker manually places the diving mobile phone case on the suction cup, but since only a few suction cups are set on the setting plate Therefore, the positioning accuracy of the diving mobile phone case on the setting board is not high, and the operator needs to take a long time to place the diving mobile phone case in the correct position, and the feeding efficiency is very low, because if the position of the diving mobile phone case is not accurate, When loading, the diving mobile phone case cannot be accurately placed inside the mold, causing the feeding to fail.

Workpiece conveying

It adopts horizontal conveying, inclined conveying and lifting conveying. Horizontal conveying can transport different items, and can adopt different conveying speeds and different conveying forms; inclined conveying can adjust the inclination angle, and improve the grip stability of the conveyor belt by using the belt or horizontal baffle with pattern The workpiece slides and disengages to ensure an accurate running track; the lifting conveyor takes up a small space and has a good effect on small cylindrical parts.

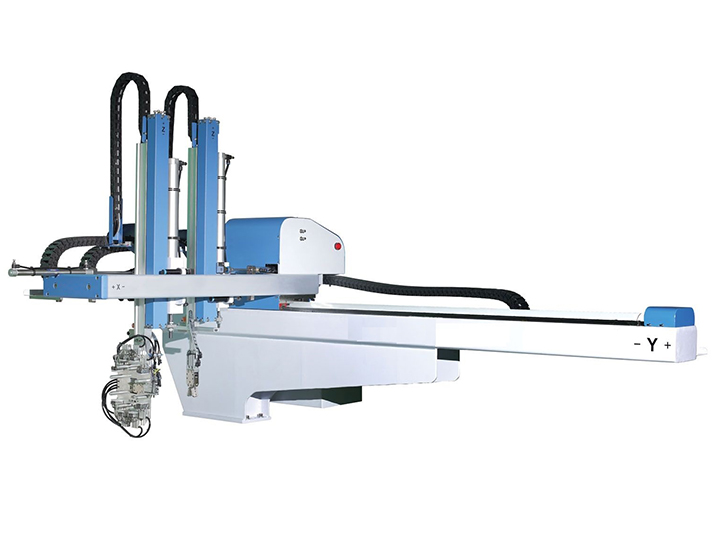

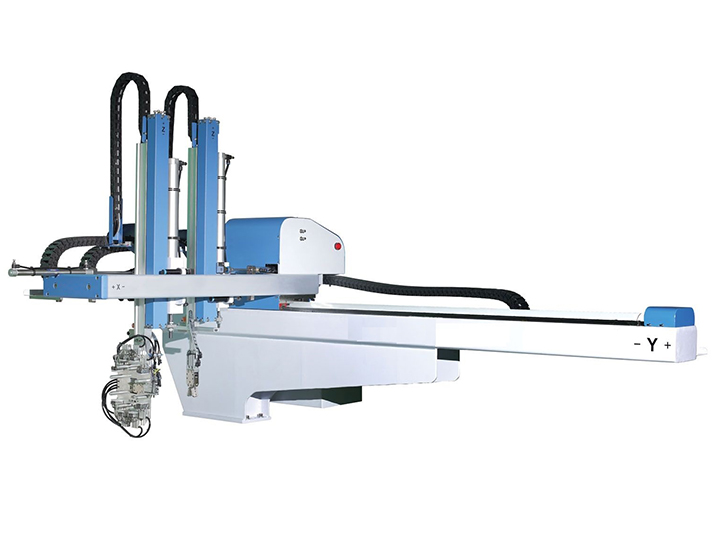

When the workpiece is transported into position, the truss-type robot is responsible for sending the workpiece to be processed on the conveyor line to the machine tool, taking the machined workpiece out of the machine tool and returning it to the original loading position. Its actions include: claw opening and closing; lifting movement; moving left and right. The opening and closing of the claws is a cylinder drive, and the lifting movement and the left and right movement are respectively driven by the servo motor. In the process of grasping the workpiece, the position and angle relationship between the claw and the workpiece must be guaranteed. First adjust the reference surface on the gripper and the corresponding reference surface on the table to reduce the angular error; then shift the gripper or the table to adjust the position error.

The loading and unloading of the chuck is completed, and the truss type robot must transport the processed workpiece to the feeding trough. At this time, the feeding is prior to the feeding and the chuck loading and unloading, and the retrieving takes priority over the loading and unloading of the chuck, so as to ensure that the whole is up and down. During the material circulation process, there is no material gripper to pick up the material.